What is a Floating Connector?

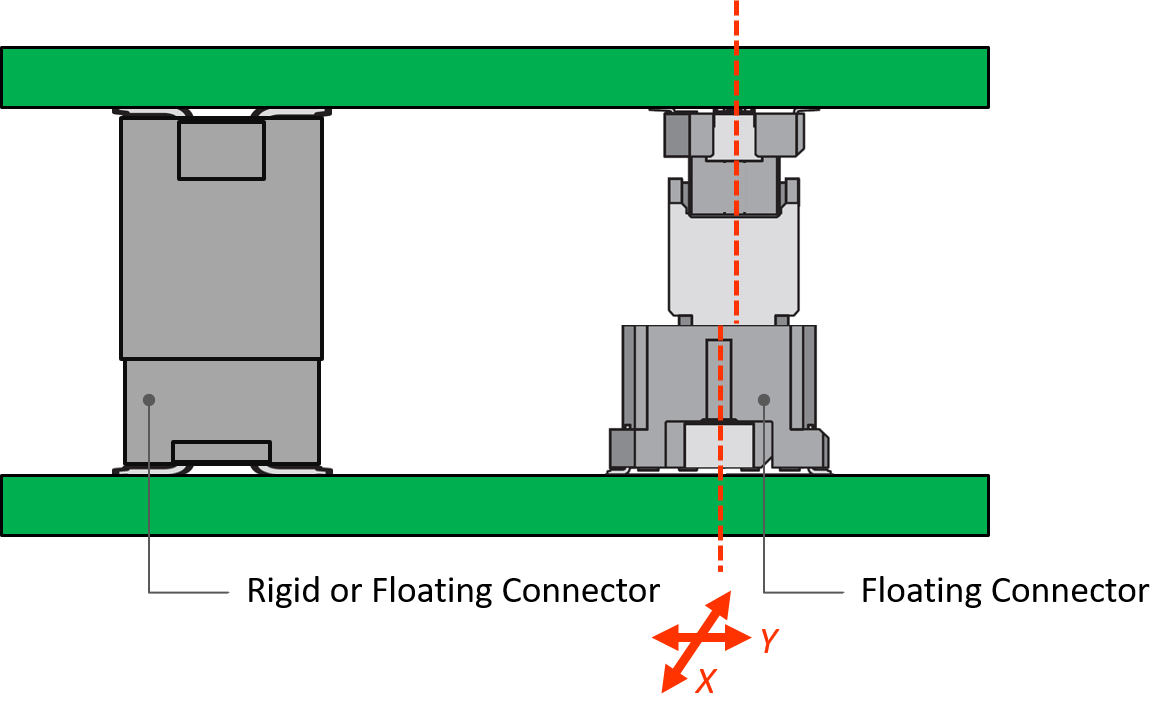

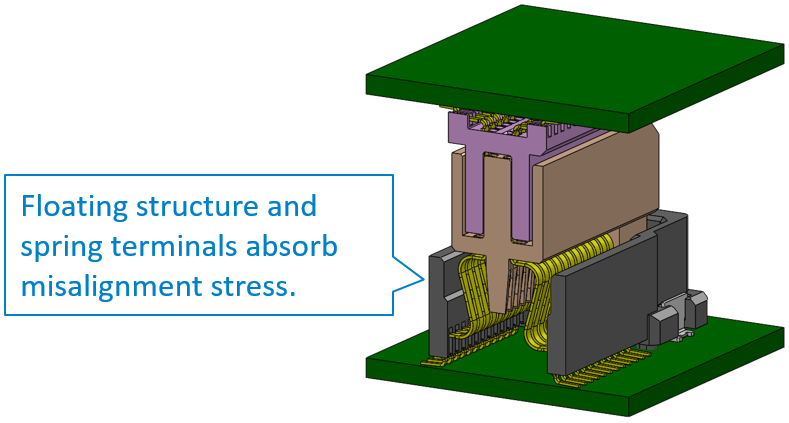

A “Floating Connector” is an electro-mechanical interconnect that absorbs misalignments in both “x” and “y” directions, that commonly occur when the interface is mounted on a PCB.

With the help of a floating structure within a connector, damage to individual elements of a PCB (such as solder points and further connector interfaces) can be prevented.

In particular, misalignments in the PCB mounting and assembly processes in “x” and “y” directions are absorbed.

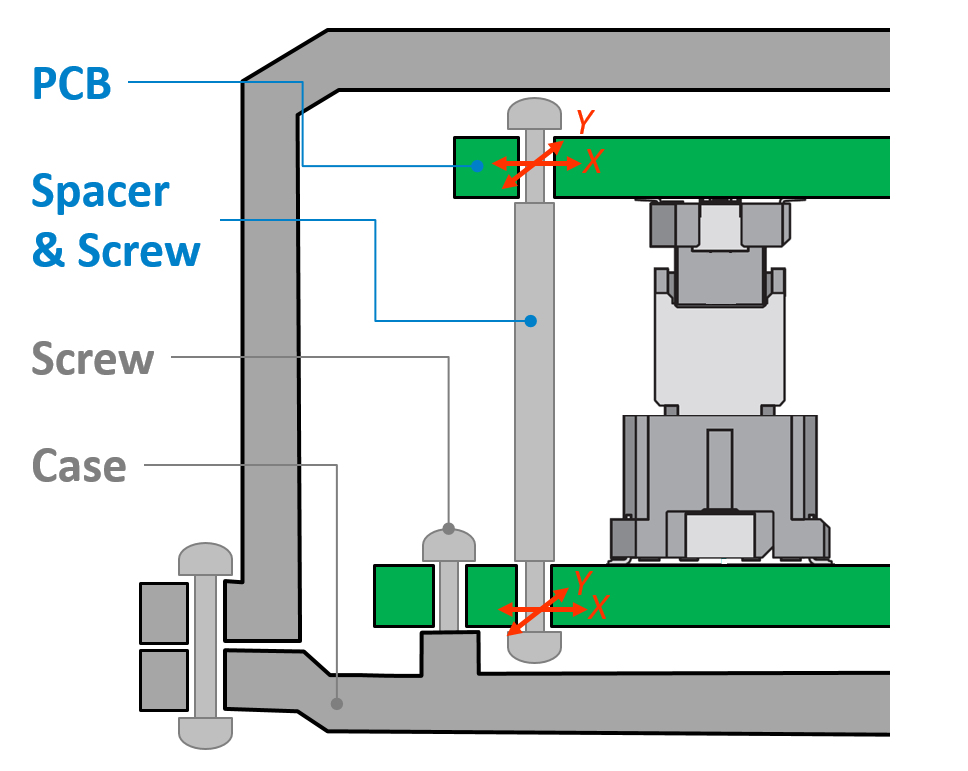

As part of the overall PCB design process it is important to take into consideration all relevant dimensions and associated tolerances.

To name a few:

screw holes, floating and rigid connector side, and the interface between the PCB and SMT connector contacts.

The miniaturization megatrend is driving the need for decreasing dimensions, which has limited PCB realestate. This has driven the necessity for automated robotic assembly, and finer pitch connectivity solutions.

What are the Features of a Floating Connector?

Mating Guide Construction (X/Y ±1 mm)

This floating connector features a special mating guide construction (X/Y ±1 mm) which enables proper alignment during PCB assembly.

Floating Range (X/Y ±0.5 mm)

The effective x and y directional floating range (±0.5 mm) allows for the insulator to move and properly mate with the opposing side.

What are the Benefits of a Floating Connector?

The usage of floating connectivity solutions offers the following advantages:

(1) Absorbs Misalignment of PCB Mounted Connectors

Various components are mounted on a typical PCB, where placement precision is a must.

Floating connectors allow excellent visual control, and ensure a production friendly structure.

This connectivity solution can absorb tolerances which makes the highly efficient and cost-effective automated PCB assembly process possible.

(2) Accommodates Multiple Board to Board Connectors on a Single PCB

Floating connectors are also useful when connecting PCBs with multiple connection points. In the case of when multiple non-floating connectors are used, where there are tolerances between each interface and the PCB, managing accurate alignment becomes very challenging.

Thus, it is not recommended to mount multiple non-floating connectors on a main PCB.

(3) Absorbs Misalignments During Assembly

Due to imperfections in production accuracy during the assembly process misalignments may occur.

This makes it necessary for the overall design to take into consideration the accumulated tolerances. With the help of floating connectors, this challenge can easily be resolved.

(4) Reduces Connector Stress after Mounting

Even a small amount of misalignment is enough to apply a small force on a non-floating connector causing stress. As the stress accumulates over long periods, it can be transferred to the PCB, other connectors, and solder joints, which can cause an irreversible failure of the main unit. Floating connectors remedy this issue by removing structural stress through absorbing misalignments.

(5) Increases Design Flexibility

As the total number of components increase, accounting for misalignment and tolerances, the overall design becomes more challenging. Where finer tolerance management can increase cost to production. Floating connectors not only help reduce misalignment, they also increase the freedom in the overall design solution.

What Applications Use Floating Connectors?

Floating connectors are used in various industrial markets.

Industrial Applications

PLCs, CNCs, industrial PCs, Sensor Units and Controllers.

Automotive Applications

Car Navigation Systems, Audio Modules, and Wireless Modules.

What are Todays Requirements of a Floating Connector?

High-speed signal transmission in industrial equipment, such as smart factories and 5G communication require higher data transmission rates (10GBASE-KR, PCIe Gen3).

There is also a growing need for a connector solutions that provides high contact reliability.

DOWNLOAD

WE CONNECT

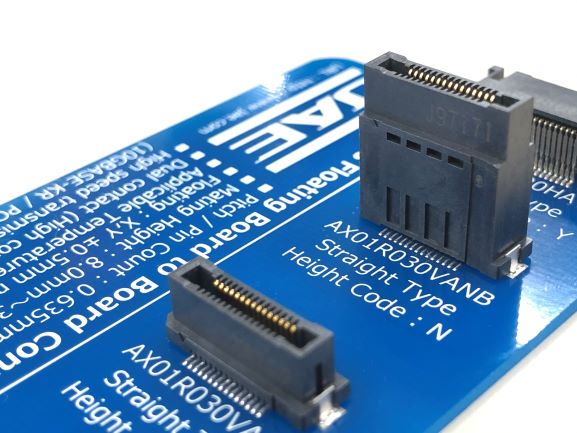

BOARD TO BOARD HIGHT SPEED TRANSMISSION FLOATING CONNECTORS

Download our comprehensive brochure to learn more about how our brand new AX01 series high speed floating board-to-board connectors are leading the way to a more automated future.

Fill out the form to download the brochure.

By submitting this form you agree our Privacy Policy.

Personal Information registered with us may be used to send free information from JAE to you.